High Security Fencing is manufactured of polyester coated welded galvanised steel wire panels with narrow and dense mesh (12.7mm height x 76.2mm width) and strong thick wires( 4mm horizontal and 6mm vertical).

Supported by post rigidly fixed and top with concertina wire coils, our high security fencing system offers maximum protection for all kinds of perimeters, including prisons, power plants, government and public facilities protection.

High-security fences are often used with surveillance cameras, motion detectors.

High security fencing features:

1, Vandal resistant, finger proof and cut proof small opening structure;

1, Thick and strong wires;

3, Strong posts firmly fixed in concrete floor;

4, Topped with anti climbing anti cutting concertina wire;

5, Topped further with barbed wire lines;

6. Central monitoring and alarm system available upon request.

Uses:

Military Bases;

Prisons;

Airports;

Critical Infrastructure, such as power plants, water treatment facilities, and communication hubs;

Border Control;

Corporate Buildings;

Government Buildings;

Storage Facilities;

Sporting Venues;

Wildlife Reserves.

OUR CAPABILITIES

We develop, supply and install high security fencing panels with posts bolt fixed to the existing boundary wall, including all fixings/accessories necessary, for various high security fencing projects.

Supply of Typical High Security Fencing System - Mesh Panels, Posts, Double Gates, Fence Accessories, Concertina Wire and Barbed Wire Fence Tops - Other combination of fence materials possible upon request.

A. Mesh Panels: Supply polyester coat welded galvanised steel wire panels in an anti climb rectangular welded mesh of 2292mm width and 3052mm high; mesh is 12.7mm x 76.2mm (H xW) and steel wire diameter of 4mm horizontal and 6mm vertical supported by post rigidly fixed on reinforced concrete floor and top with concertina coil medium barb.

B. Posts: Supply of 120mm x 60mm x 6.3mm x 3800m posts made out of hot-dip zine coated steel sheet and polyyester coated in and out to Z275 (275g/m2) in accordance with European Standard EN 10326.

C. Swing gate: Supply 3052mm x 5000mm (H x W) galvanised and polyester powder coated black RAL9005 double swing access gate with secured post 150mm x 100mm x 6.3mm x 3800 (or approved equivalent) inward opening 180 complete with free standing gate posts, rear hung with fully adjustable hinges, lockable ground bolts and anti lift brackets to include all necessary iron mongery and fittings.

D. Fence accessories:

Cover Plate 60mm x 6mm x 3055mm

MS8 x 150 Stainless Steel bolts

M8 x 80 Stainless Steel bolts

50mm x 50mm x 5mm angle iron

Other accessories including Fortinet Clip; Tensioners; Tie Wire; Tension Wire; Clip Tong e.t.c for all required installation.

Mesh panels made out of galvanised steel wires, welded and subsequently polyester coated for fencing.

The panels have round horizontal wires and thicker round vertical wires.

The horizontal wires are double every 152,4 mm (12*½”) except top and bottom where the distance is 139,7 mm (11*½”).

The panels are produced by electrical resistance welded galvanised wires and organically coated in accordance with EN 10223-7

Quality Standard References

EN 10016-2: Non-alloy steel rod for drawing and/or cold rolling,

EN 10218-2: Steel wire and wire products – General – Part 2: Wire dimensions and

tolerances,

EN 10223-7: Steel wire and wire products for fences - Part 7: Steel wire welded panels for

fencing.

Chemical composition: see table below

| Chemical Composition | |

| Element | % |

| C Si Mn P S |

<= 0.10 <= 0.30 <= 0.60 <= 0.035 <= 0.035 |

The wire rod is in accordance with the European standard EN 10016-2. The designation of the wire rod is C9D.

Polyester for Coating

Free from Lead and Cadmium. The standard colour is green

Diameter of the horizontal wires: 4,00 ± 0,20 mm

Diameter of the vertical wires: 6,00 ± 0,20 mm

Tolerance is in accordance with EN-10218-2

Tensile Strength

Horizontal and vertical wires: min 400 N/mm²

Weld shear strength

The average weld shear strength of 4 welds taken at random shall not be less than 50% of the breaking strength of the vertical wire (in accordance with EN 10223-7).

Coating

Zinc coating

The wires are ordinary galvanised and the horizontal and vertical wires have a minimum

zinc weight of 30g/m².

Organic coating

The panels are after welding subsequently polyester coated

Thickness polyester: The layer is minimum 100 Cm thick.

Adhesion of the polyester: make a scratch in the longitudinal direction of the wire, by

means of a hard metal pointed graving tool, penetrating through the metal .The length of

the scratch will be about 50mm. The coating shall not be able to be lifted from the metal by

more than 5 mm.

Resistance of the polyester to salt spray

Make a scratch in the longitudinal direction of the wire, by means of a hard metal pointed

graving tool, penetrating through the metal .The length of the scribe will be about 50mm.

Test in accordance with ISO 9227.

There shall be, after 1000 h salt spray, no corrosion beneath the polyester or loss of

adhesion in excess of 10 mm from the scratch and no signs of blistering, cracking or crazing

on any part of the specimen

Mesh Panel Dimensions and Tolerances

Mesh dimensions and tolerances

The nominal mesh dimensions are measured between the centres of two neighbouring

wires:

Distance between the vertical wires: 76,2 ± 2 mm

Distance between the double horizontal wires: 152,4 ± 2 mm, except top and bottom where

distance is 139,7 ± 2 mm

Distance between the horizontal wires: 12,7 ± 1 mm

Height of the panel

The overall height from the panel is 3052 ± 5 mm.

Width of the panel

The overall width, excluding overhangs, is 2292 ± 3 mm.

Overhang

The overhang will never exceed 2mm.

The posts are made out of continuously hot-dip zinc coated steel sheet and subsequently polyester coated. The posts are in accordance with following specifications.

Chemical analysis of the steel:

As shown in the table below

| Chemical composition | |

| Element | % |

| C Si Mn P S |

<= 0.20 <= 0.60 <= 1.70 <= 0.10 <= 0.045 |

The steel is in accordance with the European Standard EN10326. The designation of the steel is: S250 or steel number1.0242 or EN10327 designation DX51D with minimum yield strength 235N/mm²

Quality Standard References

EN 10326: Continuously hot-dip coated strip and sheet of structural steels – Technical

delivery conditions

EN 10327: Continuously hot-dip coated strip and sheet of low carbon steels for cold

forming - Technical delivery conditions.

Dimensions and tolérances:

Post dimensions: 120 x 60 x 6.3 x 3800 mm

tolerance on the cross section ± 0.6mm

tolerance on the thickness D: 10%

tolerance on the height H: ± 2 mm

Posts Coating

Zinc coating for posts:

Designation of the coating is Z 275. (275g/m² sum of both sides)

The galvanising is in accordance with the European standard EN 10326 or EN10327

Polyester coating:

Thickness: min. 602m

Colour: green RAL 6005

Polyester is free from lead and cadmium.

Adhesion of the polyester: accordance with EN 10223-7

make two scratches by means of a hard metal pointed graving tool, penetrating through the

metal and intersecting at an angle of 30° ± 5°. Lift a 30° peak with the point of a knife. The

coating shall not be able to be lifted from the metal by more than 5 mm.

Resistance of the polyester to salt spray

make a diagonal cross by means of a hard metal pointed graving tool, penetrating through

the metal. Test in accordance with ISO 9227.

After 1000 h there shall be no corrosion beneath the polyester or loss of adhesion in excess

of 10 mm from the diagonals and no signs of blistering, cracking or crazing on any part of

the specimen.

Support arm material:

Chemical analysis of the steel:

| Chemical composition | |

| Element | % |

| C Mn P S |

<= 0.17 <= 1.40 <= 0.045 <= 0.045 |

The steel is in accordance with the European Standard EN10025. The designation of the steel is: S235 or 1.0037. (ST37-2)

Quality references

ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles – Specifications

and test methods.

EN 10025: Hot rolled products of non alloy structural steels, technical delivery conditions

EN 13438: Powder organic coatings for galvanized steel products for construction

purposes

Dimensions and tolerances:

Wire extension profile bent arm: L Profile DIN1028 (St37.2) 50x50x5x540 mm

Cover plates: 60x6x3010

Coating

Zinc:

Minimum zinc weight of 325 g/m² and an average of minimum 395 g/m².

Galvanising in accordance with the European standard EN ISO 1461.

Polyester coating:

Thickness: min. 60Cm

Colour: green RAL 6005

Polyester is free from lead and cadmium.

Adhesion of the polyester:

make two scratches by means of a hard metal pointed graving tool, penetrating through the

metal and intersecting at an angle of 30° ± 5°. Lift a 30° peak with the point of a knife. The

coating shall not be able to be lifted from the metal by more than 5 mm.

Resistance of the polyester to salt spray

make a diagonal cross by means of a hard metal pointed graving tool, penetrating through

the metal. Test in accordance with ISO 9227.

After 1000 h there shall be no corrosion beneath the polyester or loss of adhesion in excess

of 10 mm from the diagonals and no signs of blistering, cracking or crazing on any part of

the specimen.

Type and dimensions

Round head square neck bolts M8x80 with standard washer DIN125 A M8 and self

breaking nut M8 out of stainless steel. (A2)

Round head square neck bolts M8x150 with standard washer DIN125 A M8 and self

breaking nut M8 out of stainless steel. (A2)

Material

Stainless steel Grade 304 (AISI) OR steel X5CrNi18-10 (EN10088-3)

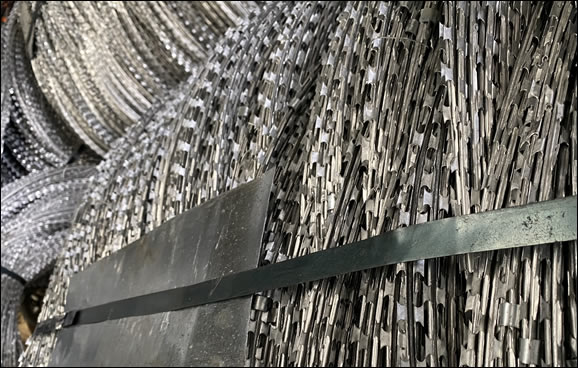

We supply barbed concertina wire and stranded barbed wire lines for perimeter high security fencing.

Barbed tape Concertina - Medium Barb

Barbed tape is made with Grade 304BA stainless steel strip with fishtail barbs and heavy galvanised steel core wire

Diameter of the coil: 730 mm

Length of the coil: recommended 12 m stretched ,diameter of the stretched coil

620 mm

Wire diameter: 2.5 mm Galvanised spring steel core wire (245g/m²)

Strip blade thickness: 0.5 mm Stainless Steel 304 or X5CrNi 18-10 ( EN10088-3 )

Barb width 16,5 mm

Barb length: 22 mm

Spacing between barbs: 37 mm centre to centre

Material: Chemical analysis of the stainless steel:

| Element | C | Mn | P | S | Si | Cr | Ni |

| % | <= 0.07 | <= 2.0 | <= 0.045 | <=0.030 | <= 1.0 | 18.0-19.5 | 8.5-10.5 |

PVC coated steel barbed wire is formed from two line wires, twisted together alternately between the four point barbs. The barb spacing is about 100 mm. The barbs are tightly wrapped round the two stranded wires. The barbs ends are cut sharp. The line and barb wires are made of PVC coated galvanized low-carbon steel wires.

Wire diameter and tolerances:

| Barbed wire diameter and tolerances | ||||

| Wire diameter Mm |

Tensile strength N/mm² | Breaking load of the strand N | ||

| Core wire | PVC coated | |||

| Line wire | 1,60 ± 0,035 | 2,00 ± 0,10 | 750 to 950 | <= 2450 |

| Barb wire | 1,40 ± 0,035 | 1,80 ± 0,10 | 750 to 950 | |

Number of points per barb

Four point barbs.

Barb spacing

100 ± 10 mm averaged over a length of 1m.

A variety of Fence Panels can be used for High Security Fencing, for Customers Options:

Welded Mesh Panels: Known for their rigidity and strength.

358 Anti-Climb Fence Panels: Named after its measurements (3" x 0.5" x 8 gauge), designed to be finger-proof, toe-proof, and almost impossible to grip, making it difficult to climb.

Chain Link Fencing: Made by weaving of steel wires into a diamond pattern, chain link fence can be used for high security with toppings like barbed or razor wire.

Palisade Fencing: Comprised of vertical steel pales with pointed tops, palisade fence is especially difficult to climb or cut.

Expanded Metal Fencing: Produced by stretching metal sheets, it is highly durable and offers good visibility.