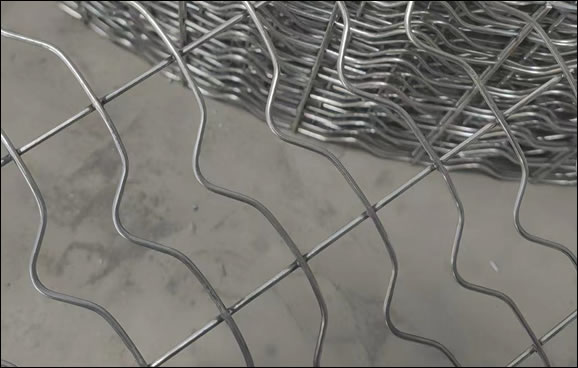

Pipeline Reinforcing Mesh is a specialized welded steel wire mesh to reinforce the concrete weight coating of offshore pipelines. Also known as Concrete Coating Mesh, Pipeline Concrete Weight Coating Mesh.

Welded mesh for pipeline reinforcement is typically manufactured from steel wire crimped with hot dipped galvanizing.

Uses:

Pipeline Reinforcing Mesh is designed to reinforce, add weight, and protect offshore oil and gas pipelines, as:

Our Capabilites

Our company has a complete set of production lines, with an annual production capacity of more than 5 million square metres. We are equipped with tensile testing devices, bending testers and other inspection equipment to ensure our pipeline mesh products meet international standard requirements.

Our company has passed the ISO9001:2015 quality system certification, has rich construction experience, and provides technical support and services for customers together with quality products.

We suply pipeline concrete coating mesh manufactured with strict requirements on materials, manufacturing process and performance. We use high-quality low-carbon steel wire sourced from large steel mills. We also implement thorough inspection throughout production, including parameters such as wire quality, weld strength, and zinc coating thickness. Our product complies with quality standards ASTM A641, ASTM A810, ASTM A185, and ASTM A82.

Common sizes

Line Wire (mm) /Cross Wires (mm) /Roll Length (m)

1.60 x1.60 x 230m

2.00 x2.00 x160m

2.40 x2.00 x130m

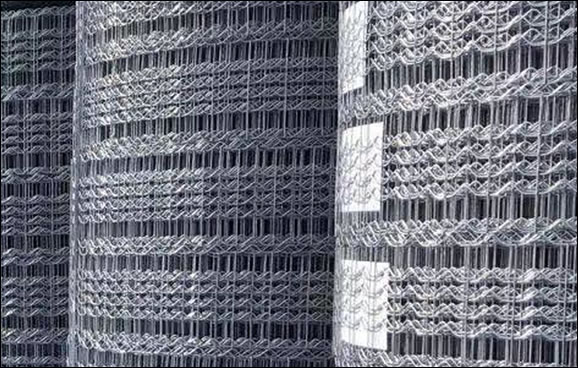

Outside roll diameter : 600mm to 900mm

Packing: Core diameter of the rolled mesh: 200mm

Rolls are packed in bundle of 5 or 6 rolls

Roll width: 190mm to 260MM

Cross wire distance: 67mm

Length of roll : 11m to 240 m

Delivery:

Surface of finished wire mesh product is neat, regular and bright.

Welded mesh rolls are compact and strong.

Welded joints are firm and convenient for transport and stacking.

The product quality is fully tested before leaving the factory, and the third party testing report can be provided upon request.

Galvanized welded mesh delivered for Canada Oil and Gas Pipeline Project

Specifications:

1-Roll width: 180 mm

2-Wire diameter:2 mm

3-Surface treatment:Zinc coated Galvanized

4-Standard: ASTM 185, A82 standard

5-Wire material: Carbon steel

6-Mesh Size:67 MM x 25.4 MM

Delivered for Middle East Marine Piping Project

Galvanized welded mesh for canal pipes continuous concrete coating

Specifications:

1-Roll width:190.50 mm

2-Line Wire diameter 2.20 mm x Cross Wire Diameter 1.80 mm

3-Mesh Size:67 MM x 25.4 MM

4-Surface treatment: Hot Dipped galvanized 5-Number of line wire/per width:8

6-Wire material: Carbon steel

7-Process:GAW (Galvanized After Weld)

8-Roll length:160 mm

Subsea pipeline welded mesh delivered for Mexico subsea construction project

Specifications:

1-Roll width:190.50 mm

2-Line Wire diameter 2.10 mm x Cross Wire Diameter 1.70 mm

3-Mesh Size:67 MM x 25.4 MM

4-Surface treatment: Hot Dipped galvanized

5-Number of line wire/per width:8

6-Wire material: Carbon steel

7-Process:GAW (Galvanized After Weld)

8-Roll length:165 mm

Customized specification, in terms of material, roll width, wire diameter and cross wire distance is available upon customer’s request.

Custom Specifications Available:

Wire Gauge (Diameter): 1.8 mm to 2.7 mm

Mesh Opening: 25.4 mm x 67 mm

Width: 190.5 mm , 180mm, custom size.

Wire Treatment: Hot Dipped zinc galvanized ASTM A810.

Crimped Wire: Crimped longitudinal wires to enhance mechanical interlock with the concrete.

Number of Line Wires/Width: 6 to 10 wires per 7½ inch width.

Quality: Manufactured to standards ASTM A810, ASTM 185, A82 standard.

Roll Length: 140 m, 160 m, 165 m, depending on the manufacturer and specific pipeline project.