Concertina Barbed Wire is a general term used to refer to Barbed Wire, Razor Barbed Wire or Concertina Wire.

Barbed wire technically refers mostly to traditional double strand twisted barb wire.

Razor type barbed wire, refers mostly to Barbed wire with razor blades, known as Razor Wire.

Concertina wire, also known as Barbed Tape, technically refers to Cross coil razor barbed wire, in the shape of "Concertina".

Concertina wire is mostly made of hot dipped galvlanized steel, stainless steel wire is also used for excellent corrosion resistance, pvc coating fusion bonding also possible upon request for traditional twisted barb wires.

Following specifications listed for references only while a variety of coils, blades and materials for concertina wire can be supplied.

Razor wire concertina, Common size for United Arab Emirates market:

Blade thickness: 0.50mm

Coil: 600-540mm (before & after stretching)

High tensile galvanised iron wire: 2.50mm diameter

In 12m roll length

Packaging: standard seaworthy packing, big coils (coil tied at 4 intervals with wire or cordstrap and then rapped with clear plastic and outside woven bag) 500 kgs coil only. Each coil must include 3 stickers specifying coil net weight, coil gross weight, coil number and wire diameter.

Technical Details for Tunis market:

Barbed wire hot dip galvanized

Diameter: 900mm

Core (central wire): 2.4 mm

Blade (L / l): 22 mm / 15 mm

Spacing: 34 mm

Spirals / Loops: 56

Roll length: 10m

Common size to Tanzania:

Razor wire BTO-22

Razor blade wire flatwrap coils with flat twin and earth cables

Material: Galvanized steel coil, carbon steel coil

Core diameter: 730mm HS (28 inch)

Blade length: 20mm

Blade width: 13mm

Blade space: 35mm

Barbed tape rolls and coils

Material: Galvanised steel sheet and wire, stainless steel sheet and wire.

Twist method: double twist.

Finish: Hot dipped galvanised.

Barbed length: 22mm

Colour: Silver

Razor Barbed Type: cross razor

Barbed distance: 6"

Specification: Wire gauge (SWG) 12# x 12#

Coil outer diameter: 700mm (70cm)

Length: 10m - 12m per roll

Barbed Wire, Hot Dip Galvanized, before powder coating:

2 mm x 50m

2 mm x 100m

Barbed wire, galvanized and pvc coated, for European market:

2.2mm x 50m

2.2mm x 100m

Barbed Wire, Green Coated GI Wire, size to Italy market:

In rolls of green color plasticized wire

50m per roll

1.8 mm thickness

2 wire double strands

4 spikes

PVC coating

The PVC of line and barb wire is applied by extrusion and made to adhere to the

galvanized base wire by the use of a thermally cured primer. This quality of pvc coating is known as "fusion bonded". (The PVC coating is in accordance with class 1b of EN 10245-2).

Coating Colour: Green 6073, various colors on request.

Barb space: 100mm

Wire diameter:

2mm line wire, 1.8mm barb wire.

Material: Low carbon steel wire galvanized.

Tensile strength of the wires

Line wire : 750 to 950 N/mm².

Barb wire : 750 to 950 N/mm².

Common size to Italy market:

Coating: Min. 240 gr./m2

Core wire min. 3 mm.

Tensile strength: 150 kg./mm2 minimum

Barbs with 4 points and spaced every maximum 60 mm

Packing: In 15m length rolls, about 26 kg

Barbed Tape Specification

| Outside Diameter | No. of Loops | Standard Length per Coil | Type | Notes |

| 450mm | 33 | 8M | CBT-65 | Single coil |

| 500mm | 41 | 10M | CBT-65 | Single coil |

| 700mm | 41 | 10M | CBT-65 | Single coil |

| 960mm | 53 | 13M | CBT-65 | Single coil |

| 500mm | 102 | 16M | BTO-10.15.22 | Cross type |

| 600mm | 86 | 14M | BTO-10.15.22 | Cross type |

| 700mm | 72 | 12M | BTO-10.15.22 | Cross type |

| 800mm | 64 | 10M | BTO-10.15.22 | Cross type |

| 960mm | 52 | 9M | BTO-10.15.22 | Cross type |

Notes:

Barbed Tape Concertina (simplified as BTC); Barbed Tape Obstacle (simplified as BTO)

Standard materials are either galvanized or stainless steel.

Special specifications available on request.

Standard materials are galvanized or stainless steel.

Barbed wire and barbed tape are fixed and installed above various steel fence panels with tie wire and v arm post.

Project examples:Twisted 4 point barbed wire is used with barbed tape concertina as fence tops for chain link fence and gate.

Materials

Barbed Wire

Quality: Barbed wire conforming to ASTM A121 zinc-coated, Type Z, Class 3, or aluminum-coated, Type A

12.5 gauge wire with 14 gauge round wire

4-point barbs spaced 125 mm apart.

Tension Wire

Tension wire, meeting with ASTM A824 or KS D 7037, SWMA-A or KS D 7011 SWMGS-7.

Wire Ties

16 gauge stainless steel twistable wire ties is used for attaching the barbed tape to the barbed wire and to the fence for ground application.

Barbed Wire Supporting Arms

45 degree outward angle 3-strand or V 6 strand arm type, in design required for the post furnished.

The arms are secured by top tension wire or top rail and bolting.

Barbed Tape, Reinforced, double coil or single coil

Toppings fabricated from 430 series stainless steel with a hardness range of Rockwell (30N) 37-45 conforming to the requirements of ASTM A240/A240M.

Stainless steel strip 0.6 mm thick by 25 mm wide before

fabrication.

Each barb shall be a minimum of 30.5 mm in length, in groups of 4, spaced on 102 mm centers.

The stainless steel core wire shall have a 2.5 mm diameter with a minimum tensile strength of 9.68 MPa and be in accordance with ASTM A478 or

STS317-W2.

Non-reinforced barbed tape, single coil, for ground applications shall be fabricated from 301 series stainless steel, with a hardness range of Rockwell (30N) 50-55, in accordance with ASTM A666. The stainless steel strip shall be 0.6 mm thick by 31 mm wide before fabrication. Each barb shall be a minimum of 30.5 mm in length, in groups of 4, spaced on 102 mm centers.

Supporting Arms Installation

After the chain link fabric installation is complete, barbed wire supporting arms and barbed wire are installed. Anchor supporting arms to the posts in a manner to prevent easy removal with hand tools with 9.5 mm diameter plain pin rivets or, with studs driven by low-velocity explosive-actuated tools for steel, wrought iron, ductile iron, or malleable iron. Studs driven by an explosive-actuated tool shall not be used with gray iron or other material that can be fractured. Use a minimum of two studs per support arm. Pull barbed wire taut and attach to the arms with clips or other means that will prevent easy removal.

Barbed Tape Installation

Install stainless steel reinforced barbed tape. Stretch out barbed tape to recommended

length, set on top of the barbed wire and "V" shaped support arms, then secure it to the barbed wire. Secure the barbed tape to the barbed wire at the two points and at every spiral turn of both coils. Install stainless steel reinforced barbed tape to the V arm, as shown on PDF drawing.

Concertina wire can be used with ground locking pegs for mobile barriers.

SUPPLY OF CONCERTINA WIRE ROLLS AND GROUND LOCKING PEGS

Project example for Turkey:

Concertina Wire

Concertina wire supplied is fabricated from high tensile wire virtually impossible to cut with standard tools.

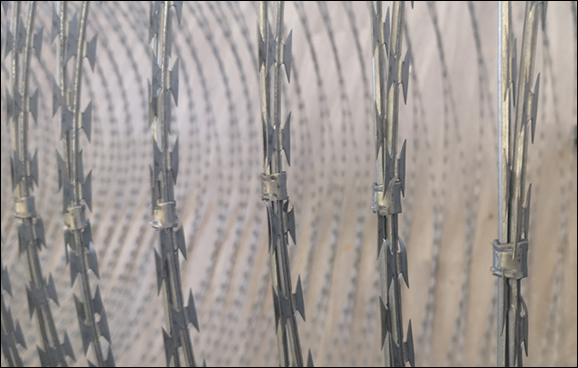

The Concertina wire is supplied in rolls and can be formed of a multitude of razor-sharp barbs at close interval as shown below:

Coil Dimension:

| Units | Diameter | Stretched Diameter | Stretch length | Spiral Turns | Clips/Spiral |

| Metric | 980 mm | 820 mm | 15 m | 54/55 | 5 |

| Ft/In. | 36 inches | 32 inches | 50 feet | 54/55 | 5 |

Core wire: High tensile wire ranging between 1400 to 1500 MPa in 2.5 mm (0.1”) diameter, core wire is galvanized steel wire.

Blades 0.5 mm (0.02”) thickness galvanized steel.

Tolerances:

The following tolerances shall be permissible:

Blades thickness: 0.5 mm +/- 0.05 mm

Core diameter: 2.5 mm +/- 0.1 mm

Coil Diameter: 980 mm +/- 10%

Spiral turns (loops): 55 nos. +/- 4

Stretch length: 15m +/- 3 m

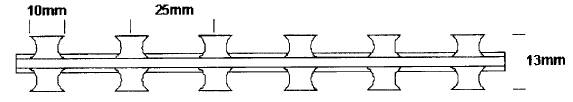

Blades width: 10 mm +/- 1 mm

Overall cross section with Blades: 13mm +/- 2 mm

Blades interval: 25 mm +/- 2 mm

Stress of tensile wire: 1350 ~ 1650 MPa

Galvanization:

The entire wire and all accessories shall be manufactured from galvanized strip with a coating 250 ~ 230gms/m2 and the reinforced steel wire shall be hot galvanized to 275gms/m2 +/- 25gms/m2.

Technical Requirements

| Concertina Wire | Technical Requirement |

| Quality Certification to ISO 9001:2000 | ISO 9001:2000 |

| Environmental Management System certification to ISO 14001:2004 | ISO 14001:2004 |

| Blade Thickness (mm) | 0.5 +/- 0.05 |

| Core Wire diameter (mm) | 2.5 +/- 0.1 |

| Coil Diameter (mm) | 980 +/- 10% |

| Number of Spiral per coil | 55 +/- 4.0 |

| Stretch Length (m) | 15 +/- 3.0 |

| Blade Width (m) | 10 +/- 1.0 |

| Overall Cross-Section with Blades (mm) | 13 +/- 2.0 |

| Blade intervals (mm) | 25 +/- 2.0 |

| Tensile Strength (MPA) | 1350 ~ 1650 |

| Galvanization Coating zinc gms/m2 | 275 +/- 25 |

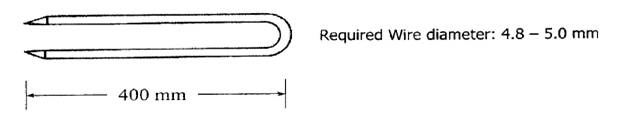

Ground Locking Pegs

The ground locking pegs as per the sketch below:

Used to secure the wire to the ground to prevent intrusion

Pieces of ground locking pegs:

Six (6) pegs per rolls of concertina wire supplied.

| Ground Locking Pegs | Technical Requirement |

| Quality Certification to ISO 9001:2000 | ISO 9001:2000 |

| Wire diameter (mm) | 4.8 ~ 5.0 |

| ½ Length of Ground Locking Pegs (mm) | 400 |

| Galvanization Coating zinc gms/m2 | 275 +/- 25 |

Samples

Samples of concertina wire and ground locking pegs shall be submitted with catalogues with full specification.

Packing and Transportation

Concertina wire rolls shall be packed on timber pallets, of suitable height, such that the pallet is stable during transportation. The rolls shall be securely strapped to the pallet in order to avoid damage to the rolls.

CERTIFICATES FOR SUPPLY OF CONCERTINA WIRE AND GROUND LOCKING PEGS

1. All items are supplied with ISO 9001:2000 Quality Management Certification.

2. Copies of ISO 14001:2004 Environmental Management System certification, specifically for: meeting designs, manufacturing of security/defence materials, environmental specifications and standards are provided.