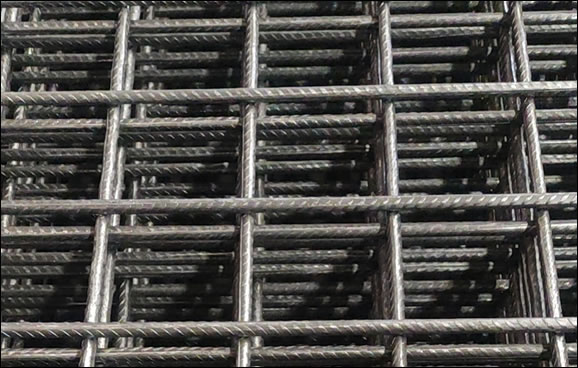

Concrete reinforcing wire mesh panels supplied with pins and bracers. Fabricated in grid, truss, ladder, panel, pile cages and various types.

OUR CAPABILITIES

Common sizes for USA market:

4' x 8' sheets

2" square hole mesh

4' x 10' sheet with 2" square hole

App: Used in concrete panel construction.

Common sizes for USA market:

Wire Mesh size: 2m x 2m x 15 cm x 6mm

Opening: 15 cm square

Iron wire: 6mm diameter

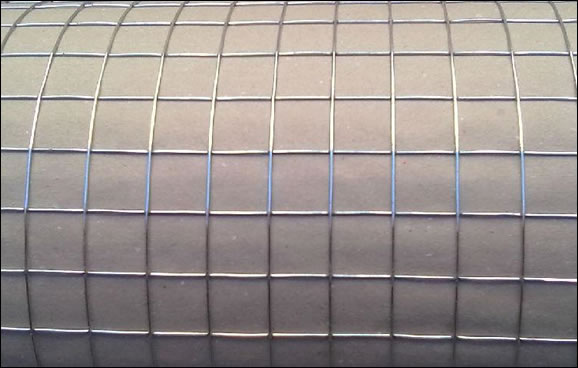

Mesh:

1/4" x 8", rectangular

Wire diameter: 1.05 mm

Square mesh size: 12.7 x 12.7 mm

Zinc coating: min. 350 gr/m2

Panel size: 1.02 x 2.50 m

App: Flat reinforced mesh panel for concrete wall reinforcement and plaster

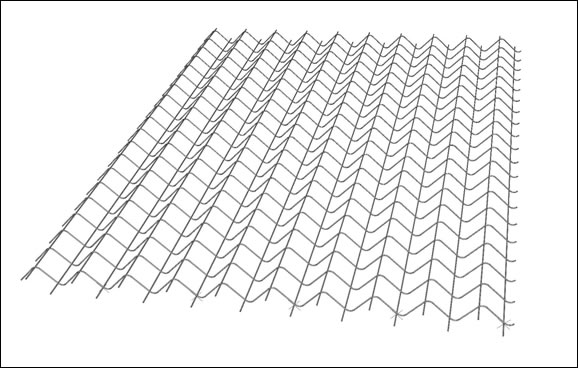

3d panels, curved with bends, galvanized and welded wire mesh panel

App: Plaster support and insulation mortars reinforcing mesh.

Wire diameter: 1.05 mm

Square mesh: 16x16 mm

Zinc coating min. 350 gr/m2

Panel size: 1m x 2.1m

Common size for UK market:

Reinforcing Mesh, sheet size: 5.80 m × 2.20 m

| Longitudinal wire ( 5.80 m) | Cross wire ( 2.20 m ) | ||||

| Size (mm) | Pitch (mm) | Area (mm2/m) | Size (mm) | Pitch (mm) | Area (mm2/m) |

| 10 | 200 | 393 | 10 | 200 | 393 |

| 10 | 200 | 393 | 8 | 200 | 393 |

Common size for Canada market:

Galvanizing and black iron with out galvanizing.

Wire diameter: 10mm wire

Mesh: 250mm x 250 mm (8 x 8)

Panel: 11.6ft length and 7.6ft height

Common size for Australia market

Mesh sheets size 5.8M x 2.2M

Wire Size 6.0mm

Mesh Size 200mm x 200mm

Weight:28.6kgs per sheet

Wire Size 6.75

Mesh Size: 200mm x 200mm

Weight: 36.4kgs per sheet

Wire Mesh ( Steel Welded Wire Fabric), steel reinforcement material for Malaysia market:

Wire thickness: 3.6mm / 4mm

Spacing: 150mm X 150mm spacing

Specification: BS4483 & MS 145, ASTM A 82, ASTM A 185, ASTM A 641

Galvanised

Type:

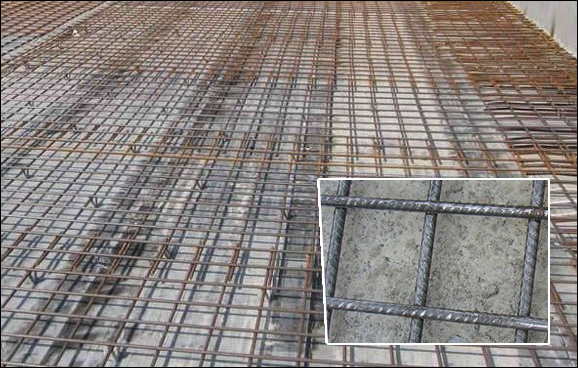

The reinforcement is either steel welded wire fabric type or cage type.

App: Steel reinforcement for limit spalling and control cracking of the concrete.

Common size for Belgium market:

Material: Iron wire

Wire diameter : 8mm-10mm

Sheet size : 5.55m x 2.1m

Mesh: 15cm x 15cm

Hole: Square

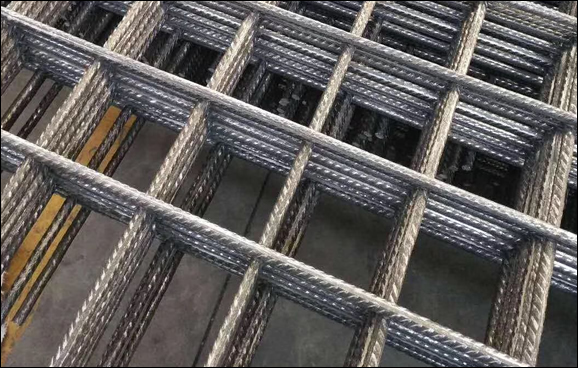

Galvanized mesh panels, welded and galvanised, mesh 19, square hole

Hot dip zinc coated after welding

Reinforcing mesh for concrete, 2.0mm wire diameter, 15cm aperture.

Galvanised Reinforcing mesh net for construction, welding net 1 inch, 8 ft × 4ft, diameter: 2.2 mm

Steel reinforcing mesh 5.8m x 2.2m, supplied to INDIA

Welded Wire Mesh Reinforcement Sheet for Concrete, welded wire mesh

152x152, 40.6/40.6 mm, mesh panels ( 2500mm x 2500mm)

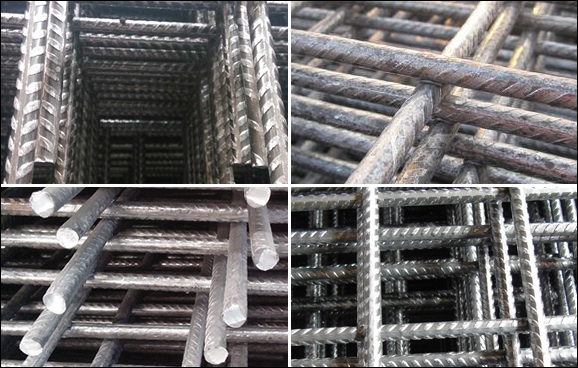

Bent Welded Mesh Sheets for Concrete Reinforcement:

Mesh 100 x 100 x 4mm diameter welded bent

Sheet size: 2m x 6m

Finish: Non-galvanised

Material: Carbon mild steel

Shipping: In stacks of sheets

Ribbed Bar Welded Square Mesh for Slab

Specification: D8, space 100mm

Min 500Mpa Yield Strength

Sheet size: 3000x2400 mm

QUALITY STANDARDS

References:

Supply and manufacture standard for Australia market

Technical specification for European market

A welded fabric of reinforcements – called "fabric" in short cut - is a unit made up of only one or several of the types of wire defined above, welded between them electrically by resistance in a producing factory of lattice, so as to form a plane network with rectangular or square meshs of which all the nodes are welded. By direction, the wire are of the same origin, of the same nuance and of the same diameter.

STANDARDS references:

Concrete Specification

1.0 SCOPE

This specification covers the supply, manufacture and delivery of steel reinforcing bars and wire fabric for concrete works.

2.0 GOVERNING STANDARDS

Reinforcement for concrete shall comply with the current issues, including all parts and amendments, of the standards listed below.

Australian Standards

AS 3600 Concrete structures

AS/NZS 1554.3 Structural steel welding – Welding of reinforcing steel

AS/NZS 4671 Steel reinforcing materials.

3.0 FABRICATION

All reinforcement shall be fabricated from the following:

• Plain bars - grade R250N steel, complying with the requirement of AS/NZS 4671.

• Deformed bars - grade D500N steel, complying with the requirement of AS/NZS 4671.

• Deformed mesh - grade D500L, complying with the requirements of AS/NZS 4671.

The types, sizes, dimensions and shapes of the reinforcement required will be shown on the design drawings.

In addition, the reinforcement shall be free of scale, loose rust, oil, paint grease or other deleterious matter that may impair the

bond between the concrete and reinforcement or cause disintegration of the concrete.

Unless nominated otherwise on the drawings, all hooks and bends, including bends at the cranked portion of bar, shall be bent

cold and shall conform to the minimum requirements of AS 3600.

The reinforcement shall not be worked in any manner which will adversely affect its strength. Any reinforcement appreciably

reduced in sections by bending shall not be used.

The details of any additional splices required from those nominated on the drawings to undertake the work shall be submitted in

writing for approval.

Reinforcement in general shall not be welded unless specifically nominated on the drawings. When required, the welding shall

be in accordance with AS/NZS 1554.3.

All reinforcing mesh fabric shall be supplied in stock size sheets or rolls unless otherwise directed by the Engineer.

4.0 TOLERANCES

The tolerances on the overall dimensions of any cut or bent reinforcing bar or fitment shall be in accordance with AS 3600.

The tolerance on the lengths of bars supplied to stock length shall be in accordance with AS/NZS 4671.

5.0 TESTING

The Contractor shall provide the manufacturer’s test certificate(s) for all steel reinforcing bars and wire fabric supplied under the

contracts wherever possible.

In the absence of a manufacturer's test certificate, the quality of the steel used for reinforcement shall be established by testing

the steel in accordance with AS/NZS 4671.

6.0 DRAWINGS

The Contractor will be provided with design drawings to enable any shop detail drawings and schedules required to be prepared.

The Contractor shall submit a checked copy of all placement drawings and schedules as required for review, but which shall in

no way relieve the Contractor of the responsibility for the work.

The Contractor shall provide a complete bar bending schedule including as a minimum, bar mark numbers, configuration sketch,

material type, length before bending, number of bars required and total weight for each group of bars.

The Contractor shall add bar mark numbers together with bar schedule number to the design drawings provided and return these

with the bar schedules for review by the Engineer, but which shall in no way relieve the Contractor of the responsibility for the

work.

The bar schedule shall ensure adequate concrete cover, as specified on the design drawings, to all reinforcing bars regardless

of any tolerances shown.

7.0 IDENTIFICATION

Groups of identical bars shall be bundled and securely tied together for shipment and tagged according to mark number and bar

schedule number.

The tags shall be fabricated of stamped aluminium or zinc strips securely wired to the reinforcing bar or wire fabric.

8.0 DELIVERIES

The Contractor shall be responsible for the scheduling of deliveries to suit the programmed job requirement.

The Contractor shall be responsible for the safe delivery of the reinforcing steel to the designated area on site and for its safe

storage on site until required for use. Any damaged reinforcing steel shall be made good or replaced as required at the discretion

of the Engineer.

9.0 SHOP ERRORS

Material improperly shop detailed or incorrectly fabricated so that its placing in the field necessitates extra work shall be the responsibility of the Contractor.

10.0 INSPECTION

The Contractor shall provide the Engineer sufficient notice and all reasonable facilities to inspect the materials prior to delivery to ensure compliance with this specification, but which shall in no way relieve the Contractor of his responsibility for the work.